An exclusive report by Reuters, which was published on 18 December 2025, details a significant breakthrough in the global semiconductor race: China has successfully developed a prototype Extreme Ultraviolet or EUV lithography machine. This development is momentous because EUV technology is the cornerstone of chipmaking.

Prototype EUV Breakthrough of China is Drawing it Closer to Chipmaking Independence.

Chinese scientists in Shenzhen have reportedly developed a prototype extreme ultraviolet lithography machine. The ongoing initiative aims to bypass U.S. sanctions and establish a 100-percent domestic semiconductor supply chain.

Extreme Ultraviolet Lithography Machine

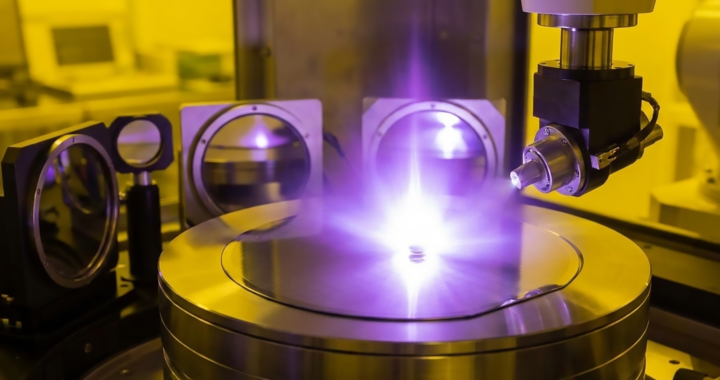

Specifically, in a high-security laboratory in Shenzhen, Chinese scientists have completed the development of an EUV lithography machine prototype. Moreover, while the machine is not yet mass-producing chips, it is operational and has successfully generated the specific extreme 13.5 nm ultraviolet light required for the lithography process.

The prototype is massive, reportedly filling nearly an entire factory floor, indicating it is still in a developmental, unrefined stage compared to the more compact commercial versions. An actual and working EUV lithography machine is roughly the size of a school bus or double-decker bus and requires dozens of shipping containers for transport.

Note that the Dutch multinational corporation ASML Holding is currently the only producer of extreme ultraviolet lithography photolithography machines. These machines are used to manufacture the most advanced chips, those based on the 7nm or below process node, that power modern personal computers, smartphones, artificial intelligence, and data centers.

Each EUV lithography machine from ASML, depending on generation, costs about 150 million to 250 million U.S. dollars. Access to such is a competitive advantage for semiconductor foundries and integrated device manufacturers like Intel, TSMC, Micron, and Samsung. Fabless companies like Nvidia and Qualcomm also depend on these machines.

The machine uses extremely short wavelengths of light in the UV spectrum to draw small circuit patterns onto silicon, and smaller patterns enable more computing per area. This process is difficult because the machine must produce EUV light from a laser hitting molten tin. The optics also need to be precise, clean, and perfectly stable so the pattern does not blur.

Building the Machine and Other Hurdles

Nevertheless, according to the Reuters report, the Chinese prototype was developed by a team that includes former ASML employees who were recruited via a covert recruitment drive that began around 2019. These employees were given signing bonuses ranging from 420000 to 700000 U.S. dollars and were instructed to work under false identifications.

Huawei is reportedly playing a central coordinating role in this initiative. It oversees thousands of engineers across various state research institutes and private companies. Moreover, because China is blocked from purchasing EUV equipment and components, the team reverse-engineered ASML technology by disassembling older lithography machines.

Other relevant components were sourced from secondary markets and other suppliers like Nikon and Canon. The goal of the entire initiative is create a supply chain that is 100 percent China-made by removing the United States and its Western allies from the manufacturing process of China. This will give China independence and geopolitical leverage.

The Chinese government has set an ambitious goal to begin producing functional chips using this domestic EUV technology by 2028. Remember that the prototype is not refined. It faces immense hurdles in replicating the high-precision optical systems or mirrors and lenses that are currently dominated by Western companies like Carl Zeiss from Germany.

Generating EUV light is also not the same as producing usable semiconductors at scale. There are five things Chinese scientists need to overcome. These include machine operational uptime, the lifetime of mirrors and lenses, keeping the process perfectly clean, overlay precision, and process tuning or using the right software settings and chemicals.

FURTHER READING AND REFERENCE

- Potkin, F. 18 December 2025. “Exclusive: How China Built Its ‘Manhattan Project’ to Rival the West in AI Chips.” Reuters. Available online